Nissan recently unveiled the new X-Trail for the Indian market. The three-row 7-Seater SUV is a little over 4.5-metres in length, however, it comes with only a 1.5-litre engine. When Nissan announced the engine displacement, to everyone’s surprise it was quite small, especially for a full-sized SUV.

But, as they say, ‘do not judge a book by its cover.’ The 1.5-litre displacement may appear tiny on paper, but, the motor is the World’s First VC-Turbo engine. Simply put, VC-Turbo is the term that Nissan uses for Variable Compression Ratio – Turbocharged Engines.

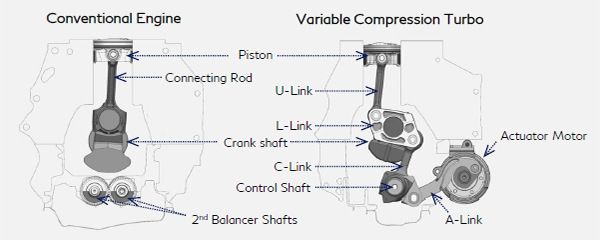

Through clever engineering, boffins at Nissan have managed to develop a new crankshaft technology that can vary the compression of the engine, depending on demand and the driver’s driving style. Unlike conventional crankshafts that oscillate the connecting rod back and forth to a set length, the Variable Compression Ratio engine is capable of adjusting the vertical position of the piston inside the cylinder.

Basics of a Combustion Engine

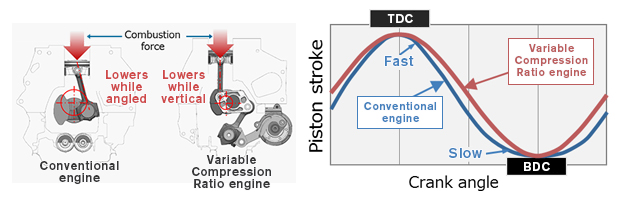

But before we deep dive into this marvel of engineering, let us first recap the basics of a combustion engine. As the piston travels from the Bottom-Dead-Centre (BDC) to the Top-Dead-Centre, (TDC) it compresses the air and fuel mixture inside the combustion chamber. The length that the piston has to travel is known as ‘stroke’. This remains constant and is governed by the connecting rod and as the name suggests the connecting rod connects the piston to the crankshaft.

In conventional engines, the compression ratio does not change as the vertical position of the piston within the cylinder remains the same. But a VC-Turbo engine is capable of changing this position through a cleverly engineered crankshaft and a harmonic drive actuator motor.

Why Need Different Compression Ratios?

A low compression engine with a ratio of 8:1, which means 8 parts of air and 1 part fuel offers more power and is ideal for high loads. The higher the compression ratio engine is more efficient, as it has a higher VE (Volumetric Efficiency). But, high compression engines require high octane fuel, which is quite expensive.

One way to improve the VE is through a forced induction system (Turbocharger or Supercharger). But, high compression engine with forced induction systems improve the VE at a cost. The rise of air-fuel mix temperature inside the engine can cause abnormal combustion (Knocking), a displeasing trait. So how did Nissan find the sweet spot between the dilemma of efficiency and power?

VC Turbo Technology

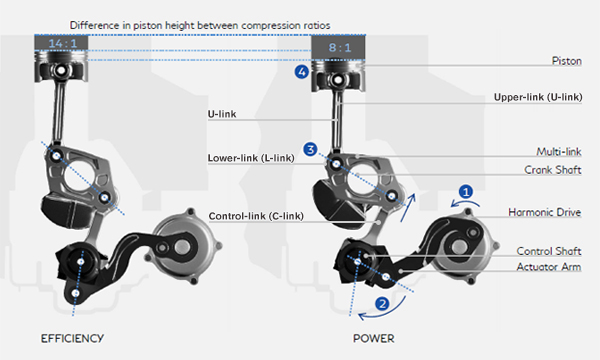

The engine on the Nissan X-Trail features a VC-Turbo whose crankshaft is connected to an actuator motor with a Harmonic Drive Reduction Gear. This VC-Turbo can sense the driving style as well as the load and demand on the engine. The harmonic drive then changes the angle of the crankshaft using a control shaft and an actuator arm. This in turn changes the compression ratio from 8:1 to 14:1 and vice a versa depending on the conditions. Thank to this, the engine is capable of utilising the best of both compression ratio traits – Power (Low Compression 8:1 for High Load) and Efficiency (High Compression 14:1 for Low Load).

Optimal compression ratio can be continuously set and changes depending on the accelerator input from the driver. When a change in the compression ratio is required the harmonic drive actuator motor moves an actuator arm that is connected to the crankshaft. The rotation of the actuator arm in turn moves a Lower-Link (L) through a Control Link (C-Link). This multi link system changes the position of the crankshaft changing the vertical piston of the piston inside the cylinder, thus changing the compression ratio from 8:1 to 14:1 and vice a versa.

Also, thanks to the variable compression technology the Upper-Link (U-Link) remain more vertical when the piston is in the BDC. Thanks to this, the reciprocating movement of the piston within the cylinder block is smoother as the friction due to the side slap is reduced. This not only improves the efficiency of the engine as frictional forces are reduced but also increases the longevity. The cylinder- on the Nissan X-Trail also features a mirror-bore finish, a technology borrowed from the Nissan GTR, which further reduces frictional forces.

A World First

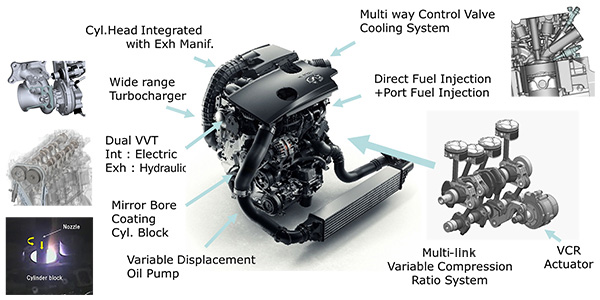

Nissan started researching on the VC-Turbo technology back in 1998 and the technology has gone through a lot of engineering troubles to optimise the link mechanism, its layout and to produce precision parts with precise heat-treatment. But as a result, the company became the world’s first auto manufacturer to start the mass production of a variable compression engine. Thanks to this, the small 1.5-litre three-cylinder VC-Turbo petrol engine with dual VVT camshaft that features electric intake and a hydraulic exhaust lift system and a twin injection system on the X-Trail is capable of producing 163 Hp of power and 300 Nm of torque.

Also Read: New Suzuki Alto will come in ICE & EV variants, will be lighter than ever