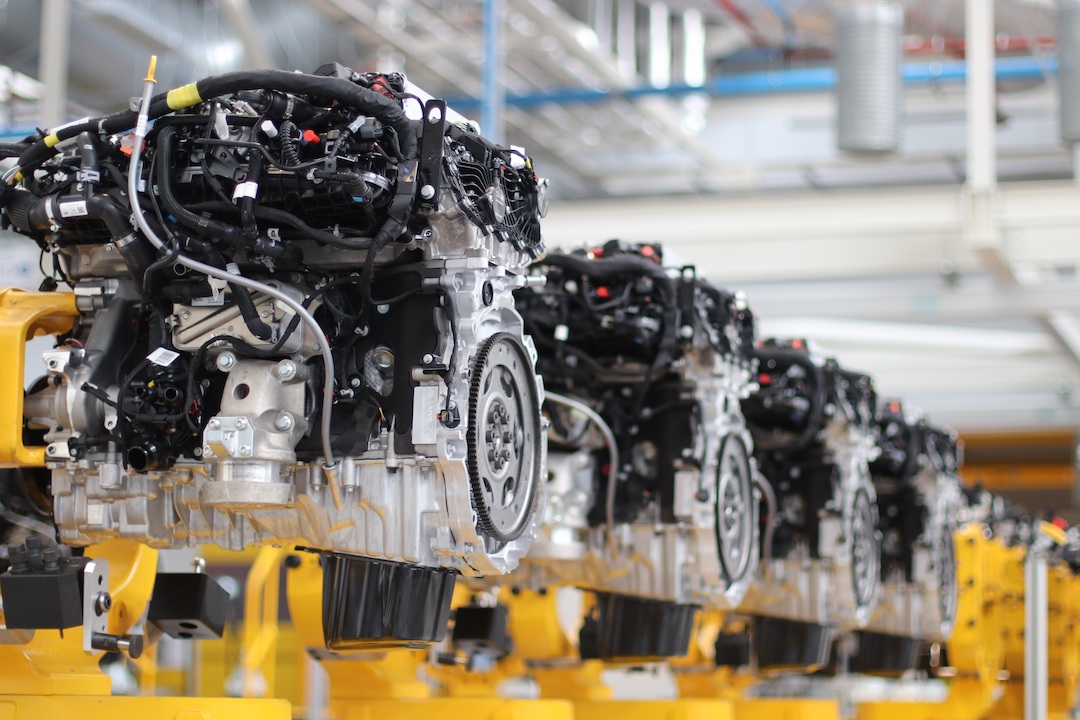

Jaguar Land Rover has announced that the brand has now produced over 1.5 million Ingenium engines and the company has announced that the new Straight-Six diesel engine joins the Ingenium family which also includes Electric Drive Units (EDU). The advanced Ingenium engines for all Jaguar and Land Rover models are produced at the Engine Manufacturing Centre in Wolverhampton, UK.

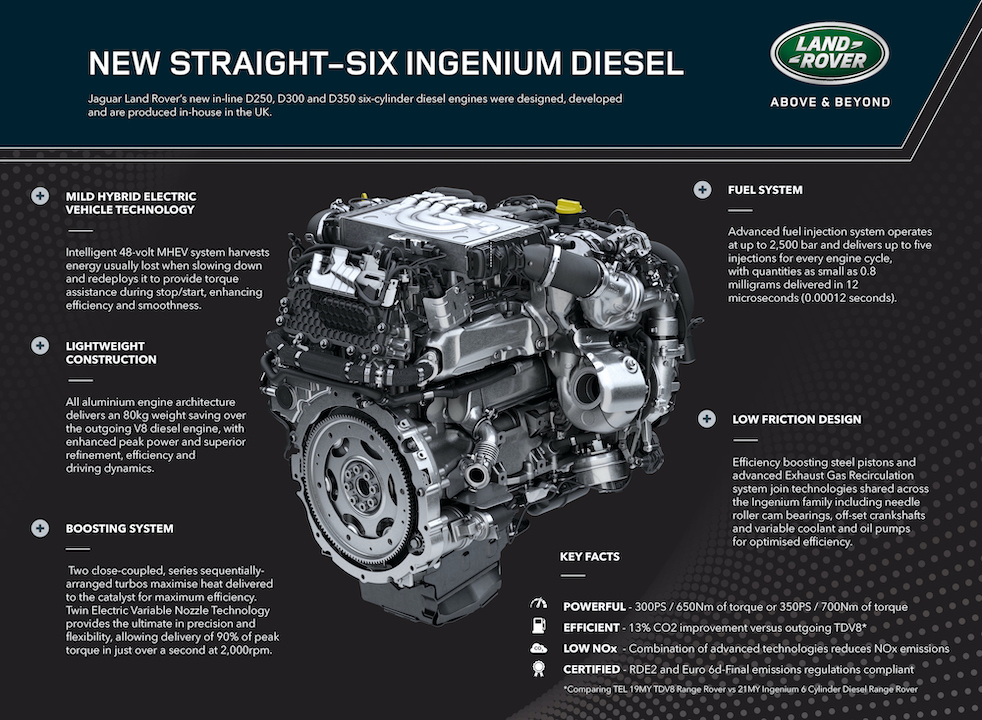

The Ingenium family includes an array of clean and electrified powertrains available in both petrol and diesel fuels offering maximum performance along with efficiency reducing the environmental impact as well as running costs. The all-aluminium Ingenium engine designs are modular, flexible, scalable and are designed, developed and manufactured in-house in the UK.

The latest addition to the Ingenium engine range is the six-cylinder diesel engine with MHEV (Mild-Hybrid Electric Vehicle) technology that not only offers optimum performance but enhanced smoothness and fuel efficiency. The new engine powers the new Range Rover and new Range Rover Sport. The Six-Cylinder MHEV diesel engine is built alongside the six-cylinder petrol and four-cylinder petrol and diesel engines manufactured at Jaguar Land Rover’s facility in the West Midlands.

The Ingenium engine family is in-line with the brand’s commitment towards reducing vehicle emissions and improving fuel economy across its vehicle range. This initiative is part of the Destination Zero mission, that engages in reducing the carbon footprint and making the environment cleaner through constant innovation.

The brand has also revealed that the Jaguar Land Rover will continue to develop its Ingenium technology along with the electrification of its model line-up and establish a concept hydrogen fuel cell powertrain solution.

The Engine Manufacturing Centre in Wolverhampton, UK, also houses the assembly of Electric Drive Units (EDUs) that offers flexibility to switch from conventional fuel to electrified vehicles. The facility in the West Midlands also houses the advanced Battery Assembly Centre at nearby Hams Hall assembling PHEV and BEV batteries enhancing the electrified ecosystem.